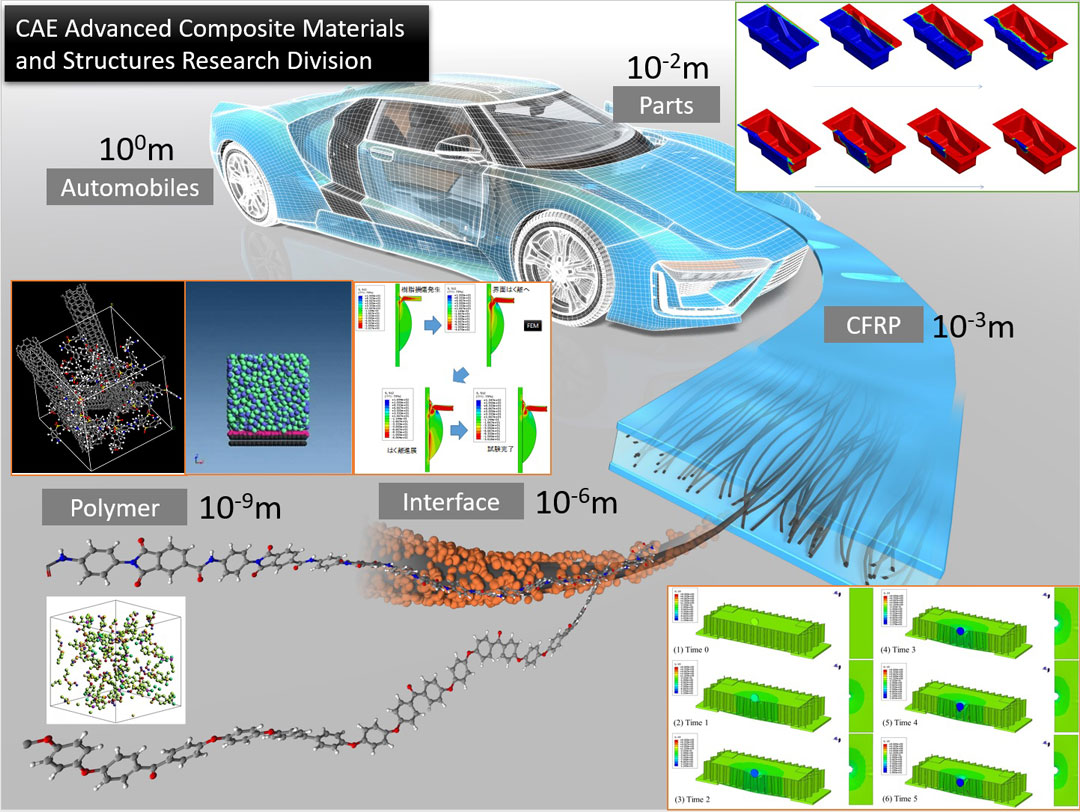

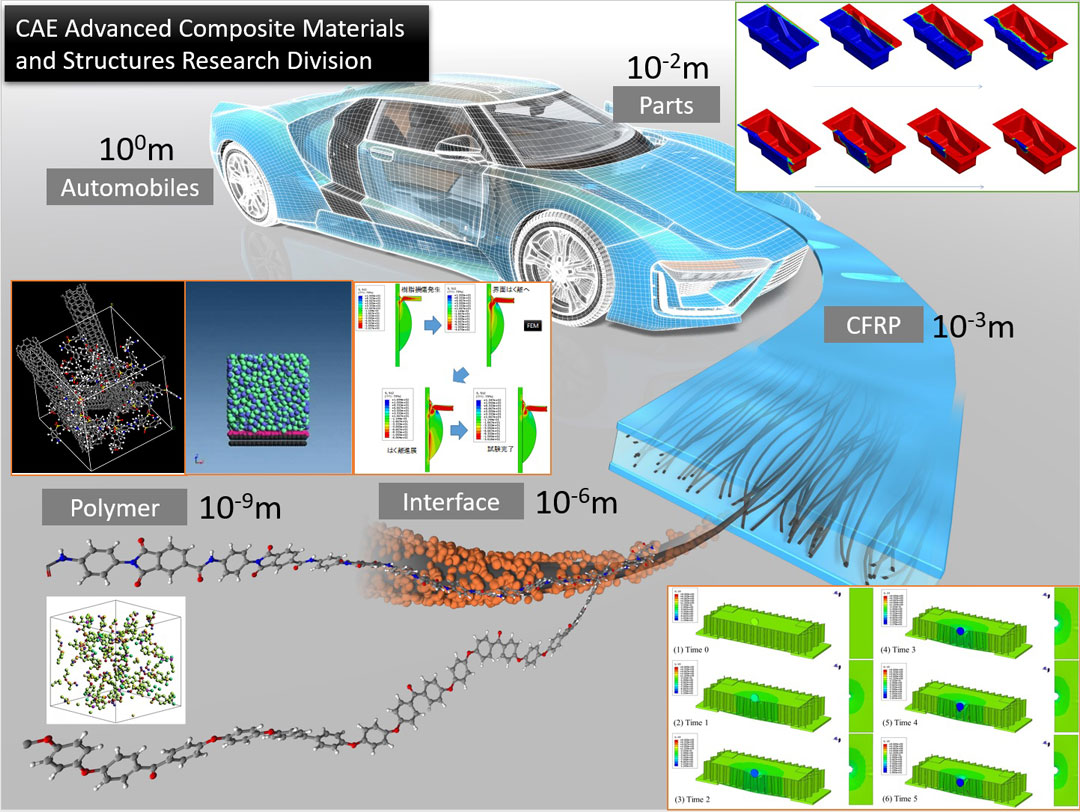

Our research contributes design and fabrication technology for composite

materials, especially for carbon fiber reinforced polymeric composite (CFRP).

Versatile multi-scale simulations are performed in the Koyanagi Laboratory,

including multi-time scale simulation (time hominization analysis). Density

functional theory (DFT), Molecular orbital (MO), Molecular dynamics (MD),

Smoothed particle hydrodynamics (SPH), Computational fluid dynamics (CFD),

and Finite element method (FEM) are employed to simulate various phenomena

of CFRP. FEM is our major simulation method. Corresponding experiments

are carried out to verify the simulated results are true. Key point of

our research is considering how nano-scale phenomena and macro-scale phenomena

are linked properly. All the research are being implemented with some contracts.

If you would have some interests, please do not hesitate to access us.

In order to secure the continuous use of CFRP, we aim to predict residual

strength and lifetime quantitatively, assuming the thermodynamic entropy

as the measure of microscopic damage and fatigue. Though CFRP becomes common

material for transport vehicle, it has been difficult to estimate the lifetime

because of complex response of composite materials and structure. We apply

“Entropy-damage”-involved viscoelastic-viscoplastic constitutive relationship

to resin properties in CFRP, and then understand various time-dependent

and multi-scale failures of CFRP through the comparison of experimental

and numerical results. Such microscopic damages and degradation are validated

by molecular simulation linked to the entropy damage model. This study

will enable the simulation of failure under multiple loadings and fatigue

for composite material.

A spacecraft departing from the Earth has to reduce its kinetic energy

when it returns to or reaches its destination planet; otherwise, it may

pass over without orbiting the planet or it may collide with the planet.

This is because a certain amount of kinetic energy is necessary to leave

the gravisphere of the earth. On planets with an atmosphere, thermal energy

is generated by friction between the atmosphere and the spacecraft; in

other words, kinetic energy is converted into thermal energy and the spacecraft

slows down allowing it to arrive safely at its destination. Of course,

the spacecraft may also burn up when leaving or reentering the atmosphere,

a basic principle in the field of aerospace. Koyanagi Laboratory performs

studies on protection from heat generated when spacecraft enter the atmosphere

of Mars and Earth. We design the heat shield for re-entering spacecraft,

the evaluation of its heat resistance, its thermal analysis, and the evaluation

of the insulation material. We perform collaborative investigations with

Japan Aerospace Exploration Agency (JAXA), so that the student in charge

of this theme in a doctoral or master's thesis will continue to work on

such research as a trainee of JAXA.

In order to design materials from an atomistic view point, we study molecular

dynamics. Our studies focus on interface bonding, graphene composites,

liquid crystals, drag delivery, biomimetics, and so on. Koyanagi Laboratory

is a key member of the molecular dynamics research group that is affiliated

to the Japan Society for Composite Materials. The research group holds

regular meetings every 3 months and we broadcast each meeting through the

WebEx system. If you are interested in knowing more about our group, please

contact us anytime.

An energy director (ED), a sharp, flat- or triangular-shaped resin bead,

is usually inserted between CFRPs during ultrasonic welding. In this study,

a two-dimensional model was used to conduct finite element analyses for

CFRP ultrasonic welding. The effects of the ED shape on the temperature

increase, deformation history, and dissipated energy behavior are discussed.

The results of the numerical simulations show that the triangular ED more

easily increases the temperature than the flat ED does, and thus its use

consumes less energy and time than using the flat ED. However, this study

indicates that a triangular ED is not always better than a flat ED. In

the ED, the temperature is distributed significantly; that is, the temperature

range between points is vast. There is the possibility that unexpected

chemical reactions such as oxidation occur. It is found that an abrupt

temperature increase is caused by a synergic effect. That is, the increase

in temperature causes the viscoelastic and frictional dissipated energy

to be remarkable, and an increase in dissipated energy increases the temperature.

Consequently, it is difficult to optimize the parameters, such as overall

pressure, frequency, and welding time, for ultrasonic welding.